Getting your CDL? Learn about air brakes in the state of New York here!

CDL Air Brakes Section 5.4 | New York State

Closed Caption

Introduction

Hi there smart drivers.

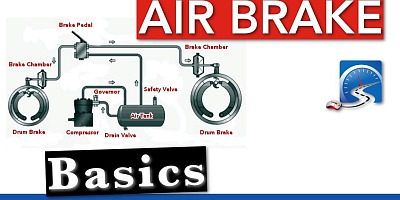

Rick with Smart Drive Test talking today about chapter 5, section 4 of the New York State CDL manual, which talks about air brakes and it is the final section of a three-part series, where I've gone over the manual and giving you clarification & more information about air brakes.

This last section is about braking with ABS— anti-lock braking systems—most of the vehicles in this day and age—all the ones that you're going to encounter—are all going to be equipped with anti-lock braking systems.

Don't Work the Day for Free:: DOT Weigh Scale Checklist |

||

• DID YOU KNOW? :: Bus & truck drivers are the only drivers that have their own police force (DOT, CVSE, MTO, etc.);• SMART :: There's a lot of paperwork you must produce for authorities at the weigh scale;• SELF-CONFIDENCE :: Bring all paperwork in one hit & impress the diesel bears! |

||

Because in most cases, it's you that gets the fine...NOT the company! |

There is some information about braking with vehicles that don't have ABS: stab braking, emergency braking - the ways to get out of an emergency situation.

Braking and steering around an emergency situation - steering is much faster.

I'll explain that later in more detail as well.

Parking brakes - one of the transitions for people upgrading to a higher licenses is that you have to use the parking brakes every time you get out of the vehicle.

Unlike our personal vehicles that have automatic transmissions and most of the time we don't use the parking brake, in big trucks & buses you have to use the parking brakes every time you leave the driver's seat.

So know that you have to use the parking brakes.

As well, downhill braking - brake fade! What happens if the low air warning comes on.

We're going to talk about all of that.

Section 5.4 of the New York State CDL commercial driver's manual and get you through - get you a CDL license - get you going up and down the road.

Get you a job & get your making more money.

We'll be right back to talk to you about that.

[OPENING CREDITS & MUSIC]

5.4 – Using Air Brakes

Hi there smart drivers.

Rick with Smart Drive Test talking to you today about chapter 5, section 4 of the New York State CDL manual.

This last section is a the last section of a three-part series.

We're going to talk to you about that in more detail right now.

5.4.1 – Normal Stops

Page 5-10 - normal stops: push down on the brake pedal come to make a general stop.

Just before the vehicle comes to a complete stop, release the brake pedal & reapply and come to a complete stop.

The reason you want to do that is to avoid a jolt, as the vehicle comes to a stop.

Because what happens is that the unit is two pieces:

1) the body and

2) the chassis.

When you brake,—if you hold the brakes on until the vehicle comes to a complete stop, when it comes to a complete stop, the body will slingshot back over the chassis.

Novice drivers are especially good at that - first couple of lessons you need to wear your neck brace! However for your purposes brake early, come to a complete stop, just before the vehicle comes to a complete stop, release the brakes, allow the body to settle back over the chassis and then reapply the brakes.

5.4.2 – Braking with Antilock Brakes

Braking with anti-lock brakes: in an emergency situation, hold the brakes - hard, firm.

You may have to post off the steering wheel to hold the brakes down.

Shutter, noise, grinding push back, all of that is normal with ABS brakes.

Look in the direction that you want the vehicle to go.

The reason for anti-lock brakes is so that the tires do not lock up and you maintain control of the vehicle and are able to steer in the direction that you want to go in an emergency situation.

The other thing about an emergency situation - make sure you have your seatbelt on.

Your seatbelt not only protects you in the event of a crash, but protects you by keeping you in the seat.

If you're in the seat you can control the vehicle; if you're not in the seat - tough to control the vehicle.

So make sure you wear your seat belt in combination with ABS brakes in an emergency situation.

Page 5-11 stab braking: push the brakes to the point of lockup, release the brakes and let the wheels roll again.

Get control of the vehicle again, and then steer in the direction you want to go and reapply the brakes.

An emergency situation - there are two ways out of an emergency situation: 1) breaking or 2)steering.

However for steering, you have to have some place to drive into, so it's important when you drive to keep space around your vehicle because you need space to drive into.

Now steering out of an emergency situation is much faster than braking; however, in a braking situation you want to do stab braking or what's called threshold breaking.

We bring the vehicle to almost lock up— most vehicles in this day and age are all going to be equipped with ABS brakes— so it's you're not going to be able - you're not going to be able to bring the vehicle to lock up in terms of braking.

But it is the fastest way to get it stopped.

So we already talked about ABS brakes, the use of ABS brakes and getting it stopped in an emergency situation.

If your vehicle doesn't have ABS brakes, you're going to do stab braking where you bring it to full lock up, release the brakes, reapply and bring the vehicle to a stop.

Hopefully before you get into a crash with another vehicle or a fixed object.

The other thing about braking in emergency situations or an emergency braking situation in particularly in rain or ice - if you have slippery conditions on the roadway is you need to be watching in the mirrors in a combination vehicle to make sure that trailer isn't coming around.

Because if the trailer begins to jackknife, you're going to have to make adjustments in either your steering, you're braking, or your acceleration in order to try and get that trailer to straighten out again.

5.4.3 – Emergency Stops

So be mindful in emergency situations in a tractor-trailer unit that you keep the unit going straight down the road.

The other thing about emergency situations in a combination vehicle is to try and brake when the truck and trailer is in a straight line.

if you're in a curve and you brake it's a good chance - there's a much higher chance that that unit is going to jackknife on you.

5.4.4 – Stopping Distance

Know that as weight increases and as speed increases for the purposes of a commercial vehicle, that your stopping distance is going to be much greater.

If you see the graph on page 5-12, a tractor-trailer unit requires another third the distance to stop as opposed to a car.

Therefore you're going to increase your following distance so you have more room to stop and bring your vehicle to a safe stop in the event of an emergency.

Following distance in a large commercial vehicles is approximately five seconds.

Watch the video here on following distance.

I'll put a card up here for you - that way you'll know how to measure out following distance and keep a proper distance for the purposes of a road test when getting your CDL license.

5.4.5 – Brake Fading or Failure

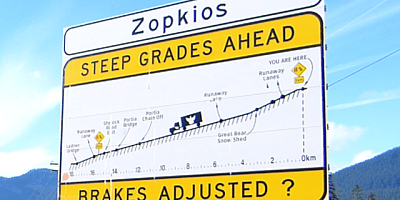

Brake fade and failure on page 5-12.

Again I'll put a card up here for you for the complete video on brake fade and that will explain to you what brake fade is.

And in this day and age, there is really no reason that you should have brake fade in a large commercial vehicle.

They're all equipped with engine brakes and engine brake technology is really great.

As long as you get in the right gear before you go down over the hill you should be good.

Remember the saying about braking down hill in a large commercial vehicle: you can go down the hill a thousand times too slow; the one time you go too fast, unfortunately you're not going to recover from that! So always get into the right gear, until you get to know that hill, until you get to know your vehicle, do you want to try and go a little bit faster.

5.4.7 – Low Air Pressure

If the low air pressure warning comes on, stop and safely park your vehicle as soon as possible.

There might be an air leak in the system.

Controlled braking is possible only while enough air remains in the air tanks.

The spring brakes will come on when the air pressure drops into the range of 20 to 45 psi.

A heavily loaded vehicle will take a long distance to stop because the spring brakes do not work on all axles.

Lightly loaded vehicles or vehicles on slippery roads may skid out of control when the spring brakes come on.

It is much safer to stop while there is enough air in the tanks to use the foot brakes.

5.4.6 – Proper Braking Technique

Page 5-13: proper braking technique - we already talked about that - hard, short, intermittent brake applications.

Right gear, engine brake on full, bring the speed down five miles per hour.

If you do in fact need to use the service brakes, let it run back up, bring it down five miles an hour.

That is the proper braking technique in this day and age.

However if you get in the right gear— five low in a 13- or 18- speed, which is the most common transmissions.

You come down over the hill, if it's less than double digits on the grade signs, the Jake (engine brake) will hold you back in a fully loaded semi trailer - 80,000 pounds.

You're not going to have any problems - Jake brakes—engine brake technology is very effective in this day and age.

If the low air warning comes on for any reason, get the vehicle pulled over to the side of road as quickly as possible in a safe location.

And I do stress safe location.

There are lots of places along the interstates that are not safe and you do not want to be standing out there! So try and get into a pull out or someplace that you can squeeze over and whatnot.

Don't try and stop in the middle of a bridge.

It's just too dangerous.

Vehicles are traveling too fast.

So try and get it over to a safe location before you bring the vehicle to a stop.

Parking brakes: this just goes without saying in a large vehicle.

5.4.8 – Parking Brakes

For those of us who are veterans-in terms of driving trucks and buses and other vehicles equipped with air brakes-not putting the parking brakes on when you stop the vehicle it's just - it's it's a little bit foreign to us.

But for new drivers getting in vehicles, I have seen them not put the parking brakes on when they parked the vehicle.

You always have to put the parking brakes on.

And just as an aside, it's a good idea to get in the habit of using parking brakes in your personal vehicles as well.

However we know as driving instructors and experts, that 85 to 90 percent of people driving automatic transmission vehicles do not use the parking brake.

There's a pin in that transmission, when you put it into park and it's really hard on that pin when you don't use the parking brake.

So on big trucks, every time you park the unit make sure you put the parking brakes on - pull the buttons out on the dash.

The yellow— the parking brake control valve— it's the yellow four-sided button you can see here in the image.

The trailer supply valve—eight-sided, octagon button—controls air supply to the trailer, and consequently applies the trailer brakes.

Parking brake - apply them! I'm in the habit, I don't put the trailer brakes on on a semi-truck because I did have the trailer brakes freeze on at one point.

They got really wet and I parked the trailer, dump the air and came back and the trailer brakes were frozen.

Essentially what happens is the shoes freeze to the drum.

So I'm just in the habit of holding my thumb on the red button, and I pull out the truck parking brakes and that is sufficient to hold the unit.

For the purposes a road test, however, make sure you pull them both out though.

When you get working, get in that habit of not putting on the trailer brakes.

There's enough heat generated in around the truck the axles and differentials and whatnot, that the brakes on the truck are unlikely going to freeze on unless you're working in sub-zero temperatures.

And the manual also says if you're descending steep downgrade and you pull in somewhere to park, don't put the parking brakes - on use wheel chocks instead.

And I don't really see that happening.

There aren't too many places that you're not going to be that don't have a distance of driving where the brakes are going to cool off before you actually get there to park.

So I don't see that as a problem.

So when you're doing a pre-trip inspection and whatnot, make sure you get the wheel chocks on.

Make sure as well that you put the parking brakes on every time you park.

Review Questions

Questions on page 5-14.

Why should you be in the proper gear before starting down the hill?

I've been in trucks with students who tried to get a gear coming down over the hill and end up going down the hill and NOT in gear! Make sure you're in gear before you start down because that's a bit scary when you're just kind of careening down the hill and NOT in gear.

Most trucks are 13- and 18-speeds: fifth gear low in a tandem-tandem, fully loaded 80,000 pounds - Jake on full.

That engine brake technology is good enough in this day and age that it is going to hold the truck back and you're not going to have to use your service brakes.

The danger is if you're not in gear and you're relying on your service brakes down the hill, you may experience brake fade.

And again, proper breaking technique downhill.

I'll put a card up here for you.

This will take you over the video on proper downhill techniques and how to do it in this day and age.

What factors cause brake fade.

As I said, in this day and age you've got to work really hard to experience brake fade in the large commercial vehicle.

It's just not going to happen.

Make sure you get the right gear, engine brake on full.

What is brake fade?

Brake fade is when you put too much pressure to the brakes, too much friction, you're holding them on down a really steep downgrade and the brakes are heating up.

There's a chemical reaction inside the shoes, causes them to melt, there's less friction.

The drum will actually heat up to the point that it expands away from the shoes and you will lose braking capabilities.

If you hold them on too much, you'll even get fire and some leprechauns and marshmallows chasing you down the road to have no weenie roast.

So brake fade - don't experience brake fade, because you held the brakes on too long! Use proper braking techniques.

If you get in the right gear, engine brake on full, you're not even going to have to use the service brakes going up and down...

going down these big hills.

The use of brakes on a long steep downhill is only a supplement to the engine brake?

TRUE.

You want to use the service brakes, just to bring the speed down five miles per hour.

Now how do engine brakes work? Engine brakes work best in a low gear at high RPMs And in a big electronic diesel engines in this day and age that higher RPMs is 17-1800.

You really don't want to run the engine above 17-1800.

If you do, it's just too hard on the engine.

So run it up about 1,800 in a low gear and go down the hill and the engine brake will hold that truck back.

When you're away from your vehicle for a short time you don't need to use the parking brakes?

Definitely FALSE!

Every time you stop that vehicle, every time you park it, put the parking brakes on.

How often should you drain the air tanks?

Daily, daily, daily.

Every day...

drain the air tanks every day.

How do you brake with a tractor-trailer unit that has ABS? You need take note whether the trailer has ABS and the truck does have ABS.

Most of the time you're just going to brake normally.

In an emergency situation, however, you're going to hold the brake down.

Hold it hard—grinding, pushback, shutter, noise all of this stuff in an ABS equipped vehicle is normal.

How do you brake when you drive a tractor-trailer combination with ABS?

For most normal brake applications, you brake as normal.

In other words, simply push down on the brake pedal and bring the vehicle to a stop.

In an emergency situation, push down hard on the brake pedal, hold and look in the direction you want the vehicle to go.

Push-back, grinding and shutter of the pedal are all normal responses of the ABS brakes.

When you're operating an ABS equipped vehicle, be sure to be looking in the mirrors to ensure that the trailer is beginning to jackknife.

If the trailer begins to move sideways, you will have to release the brakes and allow the trailer to straighten, and then reapply the brakes.

Do you still have normal brakes if the ABS are not working and you know that because the ABS light is on and stays on in the truck?

The answer is TRUE.

You do have normal brakes once the ABS fail and the light comes on and stays on.

They just revert to normal brakes.

So know that the light is on and stays on - your ABS is not working - that you can lock up the wheels.

So then you're going to have to do stab braking or what we call in Canada threshold braking.

When you brake hard, bring it to the point of lockup.

Release the brakes, look at the direction you want to go, reassess the situation and reapply the brakes hard and keep doing that until you bring the vehicle to a safe stop or you steer around the obstacle or emergency that you need to steer around to get out of that emergency situation.

So the answer is TRUE.

You have normal brakes.

The ABS stopped working.

So that concludes the chapter on air brakes in the New York State CDL manual.

This gives you further clarification and information that you need to go and write your air brake ticket and be successful on passing.

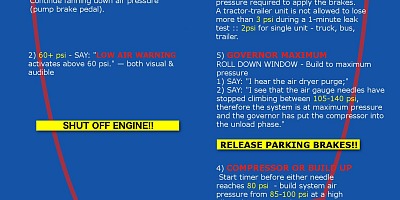

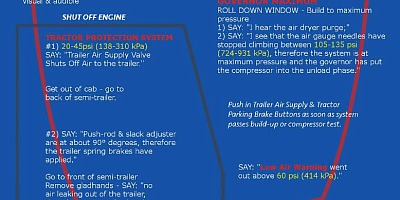

The numbers for the in-cab checks are probably your hardest part of this information about air brakes because it's straight memorization.

It's information that you need to memorize for the purposes of the test - both the theory test and for the practical test that you have to do in and around the vehicle as part of your pre-trip inspection when you go for your CDL license.

Methods to Memorize:

One of the ways that you can learn that information is to go and get yourself flash cards.

On the front of the flashcard write the test that you need to do.

For example, the governor test.

And then on the back write: minimum and maximum.

What is the maximum? How do you know that the system is at maximum? The air dryer purges and the needle stop climbing.

I hear...I see...I hear the air dryer purge, I see that the needles have stopped climbing between 100 and 135 pounds and they are no longer climbing; therefore the system is at maximum pressure.

Or the low we're warning test - tractor protection system test - whatever the test is, write it on the front of the flashcard.

Carry them around with you.

You can just turn it over and the answer to the question will be on the back of that flash card.

It's a great technique for those of you learning to get your CDL.

And carry them around.

Anytime you're sitting around waiting or doing something that allows you to look at your flashcards.

Take a couple of minutes and get the stuff into your brain.

It's going to help you out in terms of learning.

Salutations

I'm Rick with Smart Drive Test.

if you like what you see here share, subscribe, leave a comment down in the comment section.

All that helps us out.

If you need any help, any further clarification or have questions about air brakes leave us an email at info@ smartdrivetest.com.

You can see it right here below me - the email address.

As well, if you think that you need more and you want more information, the complete information about an airbrake system.

You can see here - there's a link to a course over at my website.

you can find the complete course - it has checklists and cheat sheets.

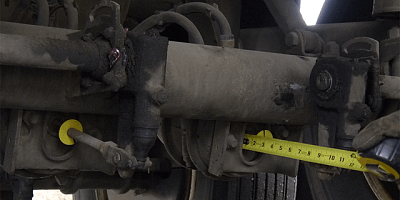

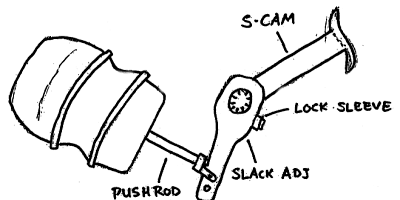

All the valves, all of the information for pry bar test, applied stroke method to test adjustment.

tests.

The in-cab checks - all of the videos - all of this stuff will be in the course and there's ten modules.

Every time you pass a module, there is a quiz of 10 questions.

The quizzes are all multiple choice.

The multiple choice questions - every answer has feedback that will give you information about the questions that you got wrong or the questions you got right.

If you happen to guess—not that we ever guess on multiple choice questions—sometimes that happens.

So there's feedback for the course.

You can find the link here and head over to my website, sign up for the complete course.

All of that for less than a hundred dollars.

I'm Rick with Smart Drive Test.

Thanks very much for watching.

Good luck on your CDL.

Remember, pick the best answer, not necessarily the right answer.

Have a great day.

Bye now.